Composition Of Steel

Steel is an alloy of iron.

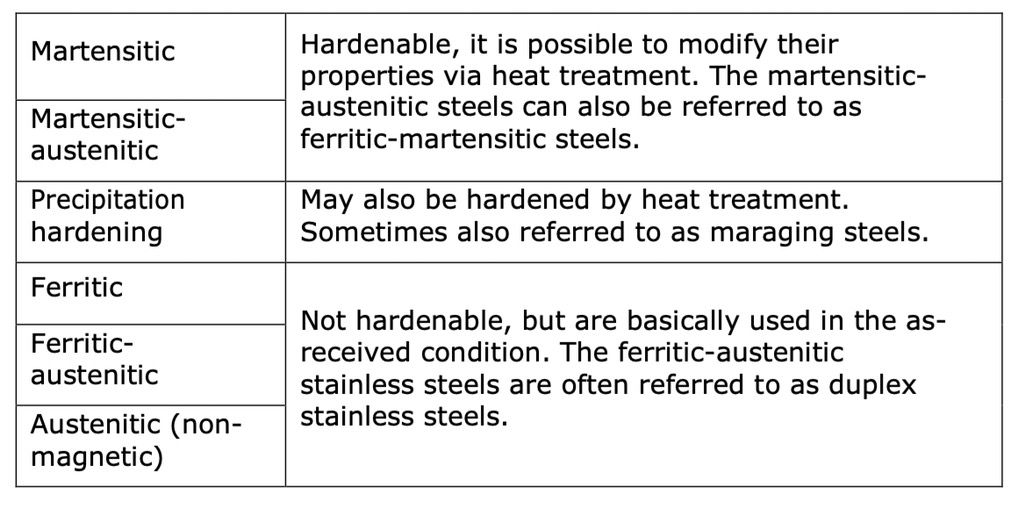

Stainless steels can be divided into six groups based on their structure at room temperature, giving a rough division in terms of composition and properties

Stainless steels are referred to as corrosion & heat resistance steels. Austenitic stainless steel is a paramagnetic material at ambient temperature unlike carbon steels which are ferromagnetic.

Carbon is added to produce desirable strength, toughness, ductility and hardness. The amount added determines which of these properties becomes dominant.

For example:

- Low carbon 0.1 – 0.3% (car bodies)

- Medium carbon 0.4 – 0.6% (general engineering)

- High carbon 0.7 – 1.1% (drills and cutting tools)

- Cast Iron 2 – 3.5% (gears, crankshafts and cam shafts)

- Grey Cast Iron 2.5 – 4% (engine cylinder blocks, gear box cases)

Other elements are blended with the steel as can be seen below to give additional properties.

- Chromium – improves hardness, wear resistance, corrosion resistance

- Silicon – deoxidiser

- Nickel – improves strength and ductility, corrosion resistance

- Molybdenum – improves creep resistance

- Manganese – deoxidiser, desulphuriser

- Aluminium – refines grain, deoxidiser

- Vanadium – improves strength, toughness and ductility

Undesirable elements include

Phosphorous – This leads to cold shortness or cracking if cold worked.

Sulphur – This leads to hot shortness i.e. prone to cracking if hot worked.

Nitrogen & Hydrogen – these elements generally cause embrittlement particularly in high strength steels.